Inside Vexcel: Precision by Design – How UltraCam Delivers Consistent, High-Quality Aerial Data

This is the second article in the Inside Vexcel series, highlighting where it all starts: Vexcel camera systems. Read on to discover why Vexcel leads the photogrammetry industry with award-winning aerial mapping systems made by Vexcel Imaging.

UltraCam systems aren’t just cameras, they’re precision instruments built to capture reality with incredible detail and reliability. Every year, they collect millions of images across the globe, powering insights about how cities grow, how landscapes shift, and how our world changes over time. But for imagery and data to be truly trusted and valuable, UltraCam has to perform with unmatched consistency.

At Vexcel Imaging, that level of reliability isn’t an afterthought; it’s built into everything we do.

A Foundation Built on Exceptional Hardware

The pursuit of accuracy starts long before a plane ever leaves the runway. It begins with exceptional hardware that’s purpose-built for measurement, not just photography, with custom-designed lenses and sensors providing the backbone for the industry-leading data quality for which the UltraCam is known.

Put simply: the results achieved by our systems wouldn’t be possible without this carefully engineered foundation.

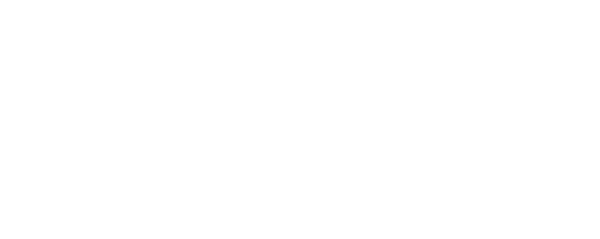

UltraCam Osprey 4.2 cone arrangement

Vexcel leads the industry as the first aerial system manufacturer to adopt the 250-megapixel Sony IMX811 CMOS sensor, bringing it to market in three new UltraCam systems launched in 2025. The new sensor is a massive leap forward in performance, and integrating next-generation sensors this quickly is only possible because we plan for the future from the very beginning.

Our design philosophy? Over-spec the lenses today so they’re ready for the sensors of tomorrow. That’s why UltraCam optics stay relevant across multiple generations, even as pixels get smaller and expectations get bigger.

Engineering Clarity: Straight Down and at an Angle

Great aerial imagery isn’t just about resolution, it’s about consistency from every direction.

An oblique camera system must capture clean, crisp imagery whether it’s looking straight down (nadir) or out toward the horizon. UltraCam achieves this with tilted oblique cones set at 45°, paired with longer focal lengths so their ground sampling distance (GSD) matches the nadir view. That balance ensures seamless mapping, accurate measurements, and better 3D modeling.

We also shift the left and right oblique sensors to capture areas closer to the aircraft at a better GSD, a subtle move that results in noticeably better detail. Planned footprints and overlaps prevent gaps or unnecessary imagery. The result is reliable, consistent, high-quality datasets that professionals can trust.

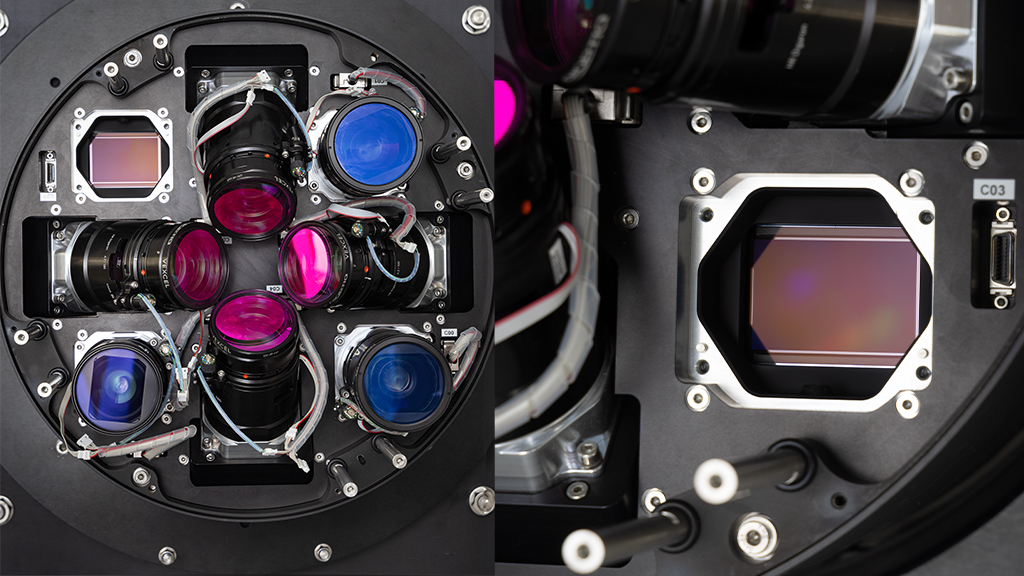

Calibration: Where Cameras Become Measurement Tools

Turning a camera into a precision measurement instrument requires state-of-the-art calibration, both geometric and radiometric.

- Geometric calibration defines the exact characteristics of the camera, from focal length to principal point.

- Radiometric calibration ensures color accuracy, even brightness, and uniformity across the entire image.

All Vexcel cameras undergo this process in our calibration lab in Graz, Austria, one of three labs worldwide. It’s here that every sensor, lens, and optical system is verified, refined, and validated before it ever enters the field.

Once calibration is complete, every camera undergoes a test flight, where its performance is checked in real-world conditions. Only when it meets our strict, ISO-certified quality standards does it earn the name UltraCam.

Calibration room in Graz, Austria

Built for the Real World, Not Just the Lab

Aerial collection rarely happens in perfect conditions. UltraCams operate in heat, cold, humidity, turbulence, and at a huge range of altitudes. All of these variables can influence how sensors behave.

Take temperature and air pressure: both can cause tiny, nonlinear geometric distortions—just a few micrometers in size—but enough to matter for precise mapping. To counter this, UltraCam systems continuously record environmental data from onboard sensors. This data enables our patented Altitude Compensation method in UltraMap, our photogrammetry software suite, which models and corrects these effects automatically.

Another example: motion blur. Aircraft move. They roll, pitch, and yaw. The ground moves relative to the plane. Vexcel’s software-based Adaptive Motion Compensation (AMC) analyzes all of that multi-directional movement and removes blur without sacrificing detail. (Look for an article soon all about AMC).

UltraCam Osprey in a plane

Processing that Protects Pixels

Our commitment to accuracy extends into processing with a straightforward principle: preserve all the information the system collects. It requires ongoing innovation, thorough testing, and the constant drive to solve complex challenges.

Once raw imagery reaches UltraMap, every correction is grounded in physics-based modeling. We don’t add “extra detail” using AI algorithms. We conserve information the camera genuinely captured and enhance it transparently.

Why? Because our customers rely on data they can trust: data with integrity.

Over Three Decades of Precision by Design

For more than 30 years, Vexcel Imaging has been guided by a simple philosophy: precision by design.

It’s why UltraCam performs at in a variety of altitudes, climates, and on the world’s most demanding projects. All of this preparation and design on our camera side is what ultimately makes Vexcel data best-in-class. And it’s why organizations across the globe rely on Vexcel imagery as their source of truth.