The Queen of Quality: A Q&A with VP Cali Cravens

Quality is one of the core pillars of Vexcel, not just as a brand, but as a company in everything we do. When it comes to delivering high quality in our imagery, Cali Cravens, VP of Production, leads a production team that is second to none. We sat down with her to discuss more about her role as a female VP leading an innovative group, as well as what it takes to deliver imagery with the highest quality possible to our customers.

Q: Cali, you’re known for being a big supporter of the GIS space. How did you find your career path and come to end up at Vexcel?

A: I actually started out as pre-med but I had a vision for what I wanted with my life and switched halfway through my undergrad to study geography and GIS. I had such a passion for the space and the future of what we could do with it, I just didn’t want to be a part of anything else. Both of my parents had careers at NASA, Lockheed, and Department of Defense and I found that arena fascinating. I came to Vexcel through my own aerospace and defense career, where my teams worked on everything from rockets to airplanes, but I had a different route in mind. Eventually I heard through the grapevine that Vexcel was launching a data program and I thought, ‘I really want to be a part of that.’ So I hounded them for months until I got an interview and then joined the Vexcel Data Program early 2018.

Q: As one of the first employees in the Vexcel Data Program, you’ve probably seen a lot of changes and experienced quite a bit to move up to become the first female VP at Vexcel. What motivated you?

A: When I started at Vexcel, I told them what I wanted to accomplish in coming here. I love this space that I get to work in; I love that I can incorporate the things I’m passionate about, the things I’ve learned from a GIS perspective across my career when I came to do operations here. At Vexcel, I’ve been a program manager, a senior program manager, senior production operations manager, director of production, and now I am VP of production. As far as being a female VP, I’ve always wanted a career I could be proud of at a company I was proud to work at, first and foremost, and I’m a huge advocate of the culture we’re striving for here. I realized whether I wanted to be or not, I am now a role model for other young women in their careers and I take that very seriously.

As for motivation, it comes down to doing something and rewarding in life. We go to school for so long and I just wanted to be a part of something to put my skills to use and to make a positive impact on the world. I feel like I can do that at Vexcel and especially as a leader, and furthermore as a female leader. I want to empower the next generation of employees no matter who they are or where they come from, and I hope to be an example that nobody is behind a ceiling of success.

Q: You’ve mentioned several roles you’ve held at Vexcel and now you’re the VP of production. You lead a team of how many and where are they?

A: First off, I just want to say how proud I am of my team, they work so hard and bring so much expertise to the table. I know the best way for us to ensure the highest quality in our production is to keep this knowledge around so I do my best to develop and bring people up. Our production and delivery team within Vexcel currently contains over 150 people on 3 continents and 4 countries (U.S., Spain, Austria, Colombia) so it’s a big, diverse group.

We are a bi-lingual team in English and Spanish and essentially span 18 working hours every day. Every single person is critical to our company culture and work ethic as we face the challenge of working across time zones to make this an enjoyable work endeavor for all of us.

Q: It’s a pretty sizable, global team you help oversee. What are some of the biggest contributions they make to Vexcel?

A: Without this team, there is no product for the company. There would be data intake from our flight ops group, but no products to deliver. This team handles everything from when the data arrives physically at the door to the moment it’s delivered to the platforms and the customers and every single thing in between.

Q: With a team of that calibre, how do they play into supporting the Vexcel pillar of quality when it comes to production and processing?

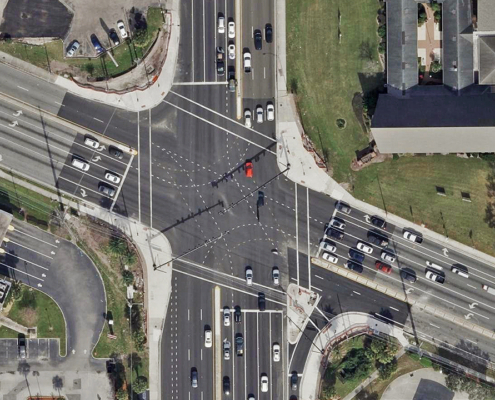

A: Quality starts even before we begin processing imagery. It starts with catching issues early and at the correct time. What do I mean by that? I mean that if we find after a collection of an AOI (area of interest) is complete, there is something possibly amiss in the data, we want to take the time to address that in the best possible way. We can’t go back in time and collect that area again because there are certain environmental factors that could’ve come into play–sun angle, cloud cover, objects moved like a car is in a different spot, or they’ve painted the house. So our goal in quality BEFORE we even start processing imagery is how can we catch or edit those tiny things we might see to help make our imagery as best as it can be.

Q: So there are some checks and balances with imagery on quality before data even comes in the door?

A: Yes, before data even comes in the door, we have automation and tooling detecting anomalies. As data is hitting these buckets in the cloud after collection, and our data units are being transferred, we are checking to make sure so many pieces of information are where they say they are. Within hours of our flight teams landing on the ground, they may already be getting messages that we’ve identified issues that may need a reflight, maybe because of weather or a sensor issue. And I’m not even touching the intensity and scrutiny that goes into making sure the camera itself inside the plane is being monitored carefully and masterfully to ensure it’s performing up to its highest level of performance. Our support teams in Austria and Colorado are constantly keeping the hardware in check.

Q: This seems like a lot of time spent before even sending imagery through the processing pipeline. What’s the benefit that you see from all of this?

A: There’s a saying that goes something like, “You can either be cheap, fast, or good–and you have to pick two.” We decided for us that taking this time was worth it for us because Vexcel has made sure quality is a top tier goal–it’s the tip of our triangle. I believe it’s one of the main things that sets us apart as a company. We literally check every single image one by one, millions and millions of images a year. There’s a list of 40 defects that might be possible and our team applies that checklist to each image. That’s dedication to quality in imagery.

Q: Once imagery has gone through this pre-processing qualification phase, what happens next?

A: Everything I just shared are the steps prior to us ingesting the data and getting it through our processing pipeline. We’re performing that quality control upfront and setting up our production team for success because we’re going to be dealing with dozens of terabytes of data per AOI; that’s a lot of data we don’t need to be retouching once it’s loaded into the pipeline.

Now that it’s cleared those hurdles, it’s ready for us to take a look at it and refine it even further. There are 72 different steps to our production. It’s amazing how many people touch everything. We have sub-teams within the production and delivery team that are hyper-focused on their area of expertise and we ensure each AOI changes many hands so it’s not biased by one person’s perspective. Production of content like this is as much an art as a technical skill and each artist leaves their mark. Having so many checks and balances and individuals involved in each AOI allows us to produce a consistent work of art each time so our customers get the Vexcel quality of standard they expect.

Q: What does the imagery go through as part of this 72-step process?

A: There are six major buckets that encapsulate our production: 1) Curation 2) AT Radiometry 3) Ortho 4) Post-processing 5) Final QC and 6) Delivery. Data is allowed to start moving through this process when we deem it as functional and ready for time to be spent on it. Each one of those stages has a quality check where everything gets scrutinized, every single value, our timelines, water, gaps – every little part of the image. We work hard to ensure high quality in our imagery so our customers trust everything they see. The only exception to this is our Gray Sky Disaster Response Program because that imagery is needed so quickly to help our insurance customers see the aftermath as soon as possible. But that is the only exception to our rule. But our goal always remains to deliver a product at the highest quality we want to achieve.

Q: What do you want customers to experience when looking at Vexcel imagery and data?

A: I want them to have a seamless experience, meaning, when they see our imagery, they don’t notice anything out of place or order. Bridges and roads need to line up, nothing is cut off, the colors look correct and natural, the shadows look natural but light so we can see the underlying features. When you look at a paper map, the color is consistent, you aren’t distracted by differences. You’re able to concentrate. When you’re looking at a digital map and you see a car cut in half or road lines that don’t line up or bridges that bend, it can distract the viewer. It can keep them from really being focused on their task at hand. And worse for human viewers, it’s actually very distracting for machines. Today’s tools and AI need high quality imagery to deliver reliable outputs and we think about the downstream customer use cases at every turn.

Q: You’ve seen the evolution of Vexcel from a new data program to now the largest aerial imagery program in the world. How do you think Vexcel continues to maintain quality in all of its data collection?

A: Look, quality is just a pivotal thing we provide. We get pushed but we are committed to delivering the highest quality of imagery possible and that takes an investment of time to deliver a product in the way that we do. In the beginning, I would joke that we were literally building the airplane as we were flying it. I was doing rapid fire interviews to bring people onboard because it was important to me to onboard people in groups so that I could get their behaviors, attitude, and process and flow to match so our production would be good. And every year we continue to add multiple aspects of quality. We really have streamlined a process over the last 7 years or so of delivering the highest quality imagery available.

Q: To wrap this all up, we really wanted to drive home why Quality is a key value and pillar for Vexcel. Why would you say it is?

A: Quality is a value we hold at Vexcel because we know that there are so many uses for this data now and in the future. And we have no idea what all these other customers, these tangential companies, all the people downstream are creating. And we have the utmost respect and highest regard for what they’re going to do with that data in the future. It is our responsibility to ourselves, to our customers, and the future of technologies they are creating to always be right at the cutting edge, be right at the maximum possible quality we can attain. Then, as new technologies become available, to us, we’re going to level up. Even before a customer asks us so we can be ahead of it, so when a customer does come and ask us and say, ‘Hey, we have this new AI model we’re training and we want to purchase data in order to use it for that and these are specs we need…’. Well, every time we hear that, we pride ourselves on saying ‘Yeah, we’ve got that. We’ve got you already.’

If we don’t have something, I can tell you right now that we are chasing it, discovering how can we achieve it. The truth is, we’ve always had a predetermined path for excellence and quality in what we were going to accomplish in the data program, thanks to the software and hardware build in Graz by the Vexcel Gmbh and Vexcel Imaging teams. They build such high-quality camera sensors and software for phenomenal image and data capture–and we are pushing the boundaries of speed with technology. But our future of tech and quality has been growing brighter and brighter–I can’t wait to see what’s next.